|

|

|

|||||||

| C4 Open Discussion General and technical C4 Corvette discussion - ownership, maintenance, repairs, modifications, tuning |

|

|

|

Share | Thread Tools | Search this Thread |

|

|

#1 | ||||||

|

C4 Mod

Barn Raising II,III

Join Date: Jan 2011

Location: Cincinnati, OH ....ΜΟΛΩΝ ΛΑBE....

Posts: 13,838

Thanks: 1,309

Thanked 7,728 Times in 3,438 Posts

Gameroom Barn Bucks: $19752494

|

The Dana 44 has opened my eyes to a whole new level of crap as far as parts suppliers and misinformation from the so-called experts so I thought I would start a thread and address a few of those issues. I started one a while ago but it was early into the process. Rather than go back and try to update everything, I figured I would start fresh with a new one. Some of it is probably a repeat.

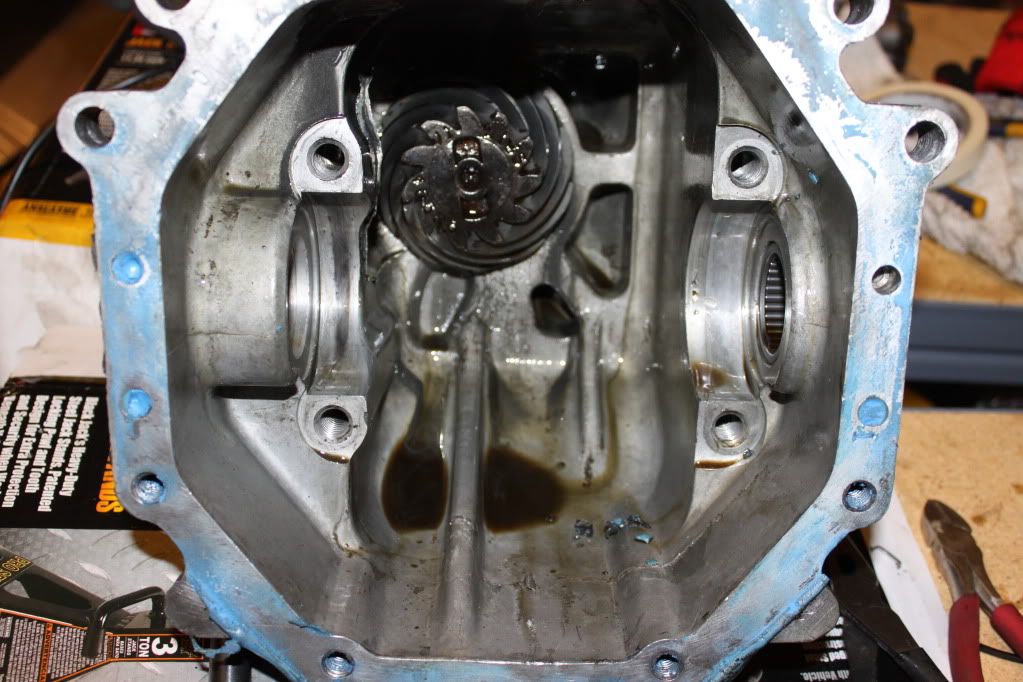

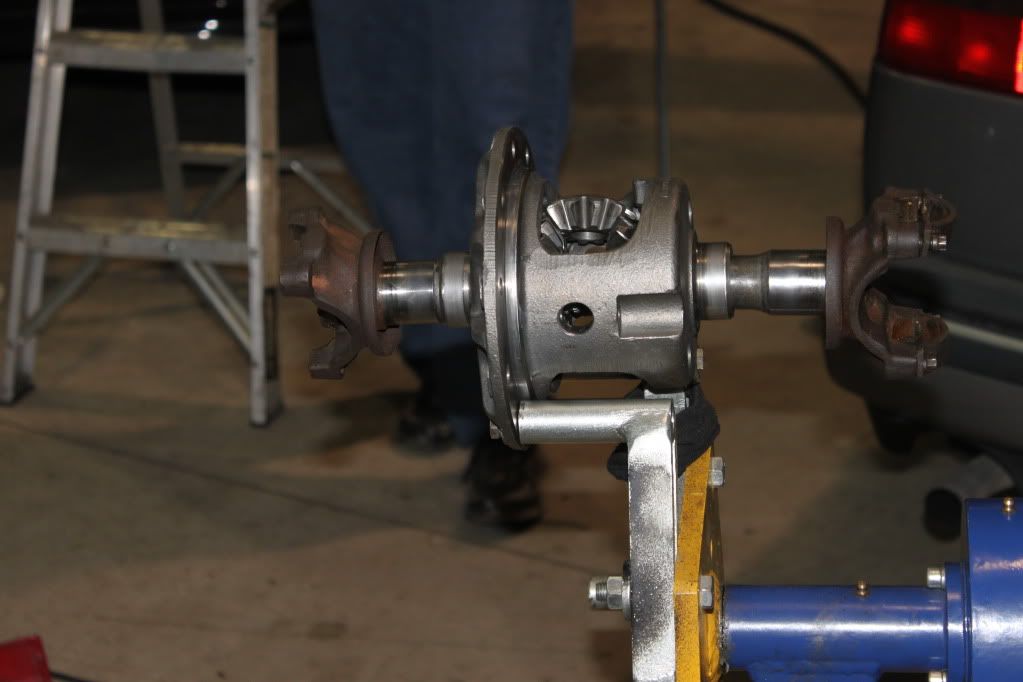

This whole thing started because the last time I had the car on the track, both halfshaft seals started leaking on me. When I say leaking, I mean LEAKING. I should have known something much worse was going on inside. When I pulled it apart, the fluid was smoked, despite the fact that most of it was very recently added. There was also a lot of metal in the bottom of the case. As soon as we saw that it became an easy choice to do a full rebuild instead of just a change of the halfshaft seals as I had originally hoped. I'm not going to do a full rebuild writeup because there are a few resources out there that are pretty well written. Here is the service manual for the limited slip: Trac Lok service manual (pdf) I will add a few notes to things that I learned the heard way. 1st, do your best not to screw up the snap rings that hold the yokes in place. They are pretty much impossible to get and are not the same as the ones in the Jeep (as I was told). They are actually differing sizes during the original manufacture and are responsible for the amount of play in the axles. The tolerance for endplay in the yoke should be measured to between .0005" (.013mm) to .0085 (.216mm) and is adjusted by using the various sized rings. I was finally able to buy an assortment from Tom's Differentials - Home of MADE IN THE U.S.A. however, since he won't ship anything less than $25 I also ended up with some t-shirts.  Next. Do NOT trust a website that says the clutches are for a Dana 44. I bought some from an online store and it turned out that they were for a 36. Another  . .I finally got them from Zip, but they were (and still are) misplaced on their website too. Here is the correct link: Dana 44 clutches Also from Zip, I used this kit for the bearings etc. The one issue that I had that I haven't resolved is that the shims were a lot different than the ones in mine and wouldn't work. Luckily I had the help of a good mechanic who had some shims that did work. Dana 44 rebuild kit I'm not sure if it is the chicken or the egg, but when I pulled apart the limited slip, there was a spherical washer missing that is supposed to be on the outside of the side gear. With this gone it gave .0030 play which made everything loose which led to destruction of every bearing inside of the rear end. The bearings on the carrier fell off (are supposed to be pressed on), the carrier itself fell out rather than being pressed tight as it is supposed to be, the backlash was a HUGE amount... long story short, the whole thing was sloppy. The last part that was a colossal pain in the ass were those spherical washers. They really shouldn't have been difficult to find, but GM has the wrong part number on their drawings!  I ordered them. They came in wrong. I called another dealer to see what happened, they had the same wrong part number. Apparently I am the only person who has ever needed these things. Finally, after a lot of time, research, and wrong parts I was able to get them from Tom's Differentials (and some more t-shirts to make $25). I ordered them. They came in wrong. I called another dealer to see what happened, they had the same wrong part number. Apparently I am the only person who has ever needed these things. Finally, after a lot of time, research, and wrong parts I was able to get them from Tom's Differentials (and some more t-shirts to make $25).    Twisting out the side gears:  Junk clutches:  Now, after MONTHS of trying to get all of the parts together and multiple times ending up with the wrong part it was on to reassembly... The parts:  The service manual lists a few specialty tools that are required. They certainly would make the job easier but we managed without. The hardest to overcome was a spreader tool used to hold the pinion gears in the limited slip unit. We twisted the gears in using the half shafts and some patience. To get the spherical washers in, you have to spread the gears against the clutches to create some clearance. We made a separate spreader for each side out of some threaded rod, nuts, and washers. It ended up working like a champ.  Twisting in the side gears:  Homemade spreader:   Snap rings... worth 100x their weight in gold.  Trac Lok finished:   Installing pinion seal:  Test fitting carrier/setting backlash:  Ready to go back into the car...  Sorry Pete... this is what it is supposed to look like...  Lastly, a shout out to the shop dog!

|

||||||

|

|

|

||||||

|

|

#2 | ||||||

|

Charter Member

|

|

||||||

|

|

|

||||||

|

|

#3 | ||||||

|

C4 Mod

Barn Raising II,III

Join Date: Jan 2011

Location: Cincinnati, OH ....ΜΟΛΩΝ ΛΑBE....

Posts: 13,838

Thanks: 1,309

Thanked 7,728 Times in 3,438 Posts

Gameroom Barn Bucks: $19752494

|

Exactly. Lots and lots of

There isn't much that I won't try to dig into on a car but I never imagined that rebuilding a rear end would turn out to be a 3 month ordeal. Along the way my friend's father, who has been a mechanic for 40 years as well as an NHRA Pro Stock crew chief gave some great help in identifying and fixing all of the things that were screwed up. He couldn't believe that it didn't just explode the way it was. You would not believe the bearings that came out of it.  I think we finally got to the root of the problems with that spherical washer that was missing. You need the spreader tool to get them in and I'm guessing that whoever put it together last time decided that wasn't something important enough to do right. .0030" play in that gear leads directly to play in the half shafts which leads directly to the destruction of everything else. In the end, there weren't a lot of parts that we didn't have to replace. Luckily the ring and pinion were still in decent shape (although there were some very uneven wear marks). If it had gone much longer they would have been toast too. The backlash was almost .0020"!! |

||||||

|

|

|

||||||

|

|

#4 | ||||||

|

A Real Barner

Join Date: Jan 2011

Location: Oklahoma City, OK

Posts: 4,030

Thanks: 1,992

Thanked 1,418 Times in 706 Posts

Gameroom Barn Bucks: $882805

|

Good write up. I don't have the 44 but I would assume the 36 is about the same. I will be doing gears as some point in the future.

|

||||||

|

|

|

||||||

|

|

#5 | ||||||

|

Barn Stall Owner #120

Join Date: Jan 2011

Location: Southern California

Posts: 10,514

Thanks: 2,209

Thanked 6,070 Times in 2,554 Posts

Gameroom Barn Bucks: $9282448

|

good write up. Bryan, you seen my work and yes, it is supposed to be that clean.

|

||||||

|

|

|

||||||

|

|

#6 | ||||||

|

Vette Barn Crew

Join Date: Jan 2011

Location: Irvine Ca

Posts: 141

Thanks: 1

Thanked 17 Times in 13 Posts

Gameroom Barn Bucks: $1215

|

After my Dana 36 debocle and the lack of help I got.....I found a nugget of gold

John at SW Gears in Huntington Beach Stop wasting your time with the "regular" Vette supply houses looking for parts and misinformation. John was a top 25 GM technician and taught courses on Dana 36/44 for years. He has all the part you need as well as the 'actual' correct info......Please not mention online forums to him as he correctly points out how much damage can be caused by "half truths" There are a lot of guys that build motors and trannys....but for some reason the D36/D44 is an enigma for the vette enthusiast forums. Anyway, don't get stumped again or buy the wrong parts again....just call John and you'll get all the help/parts you need. |

||||||

|

|

|

||||||

|

| Thread Tools | Search this Thread |

|

|

Support the Barn: |

Download the Mobile App; |

Follow us on Facebook: |

||