The Axial Vector engine...........

Most know us as a speed shop. Behind the scenes, we are much more. Our "sister" company, Enginetec, is an engineering firm, specializing in product development and R&D. From big cubic inch marine gas engines, to high horsepower diesels, we do a little bit of everything.

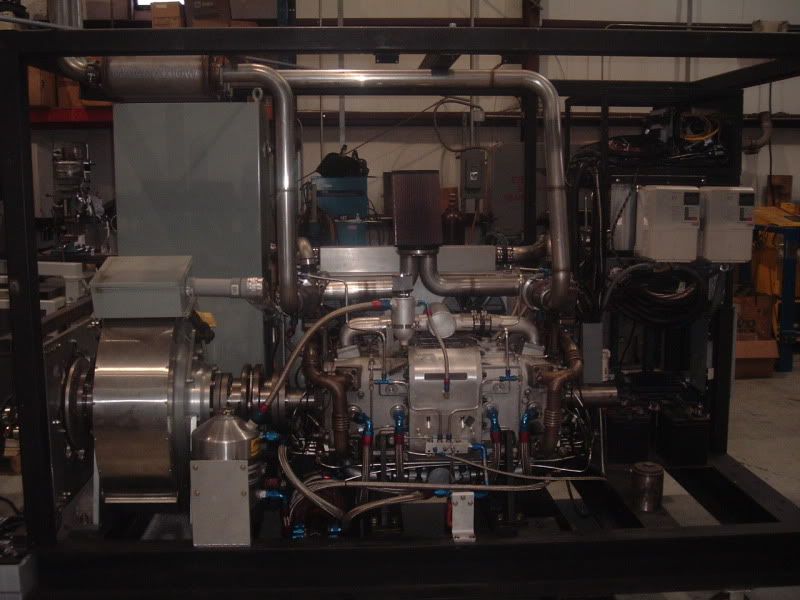

One of our most unique challenges has been the Axial Vector engine. In late 2007, the Axial Vector group approached Douglas Hahn (Pres.of Va Speed/Enginetec) to provide program support and design as the engine program matured. In mid 2008 EngineTec was approached to finalize testing and design. Douglas asked his crew at Virginia speed if this they were up for a challenge. A group never to back down from a good project, the team said yes and the project was moved from Roush Engineering in Detroit to EngineTec/Virginia Speed in Virginia Beach.

Through engine simulation, FEA work, along with gut checks that come from our combined years of racing, both gasoline and diesel, automotive and offshore, our personnel were able to make significant contributions that allowed AVEC to meet company milestones.

In addition to all the mechanical engineering that went into this project, we had to re-write parts of the control system software from control level up. This was a proprietary system, so some of this was done by the software engineers, some by Douglas, Shawn, and myself. We took data gathered on the Schenck diesel dyno, and in-cylinder pressure transducers (for each cylinder and both turbochargers) and used this data to input into the control system. In addition we had to characterize sensors, pre-injection, main injection, post injection, timing, rail pressure etc. This was comparable to writing GMs program to run an engine….Then we had to tune it.

Below are a couple videos of the Axial Vector. One is a 9 minute video made by the company talking about the technology and it's possible uses. The second is of the engine running on our Schenk diesel endurance dyno. In that video you can see some of our data gathering equipment. About 24 seconds into that video, you get a shot of a computer screen showing the cylinder pressures, provided by PTrac/Ptran OPTIMUM POWER with Kistler in-cylinder transducers. A few seconds later, the camera pans to the left and down, and you can see on one of the screens, the engine is making 640 ft lbs of torque at just over 500 rpms, and this is on no boost!

This engine, although diesel based, was engineered to run on alternative fuels, we even used Palm nut oil. Palm oil is the most abundant cooking oil on the planet, is renewable, and has low emissions. Just as a side bar, we received a pallet of palm oil from Malaysia, then through transesterification we made the palm nut oil fuel it ran on in the one video.

Shareholder’s letter from Avec Chairman Samuel Higgins

http://www.axialvectorenergy.com/pdf...hareholder.pdf

Quoted from Chairman Samuel Higgins:

Headed by Douglas Hahn, whom you will see in our videos today conducting the engine tour, is the “glue that welded all the pieces together”